XTR101

575 INR

Product Details:

- Input RTD Sensor / Current Input

- IP Rating Not rated

- Power Source External Dual Supply (+15V/-15V)

- Features Low drift, High accuracy, Monolithic Design

- Resolution Analog IC, not digital

- Interface Through-hole DIP / PCB mount

- Output 4-20 mA Current Loop

- Click to View more

X

XTR101 Price And Quantity

- 10 Piece

- 575 INR

XTR101 Product Specifications

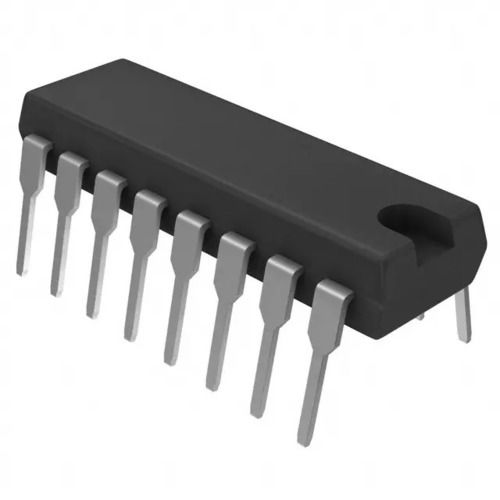

- 22.9mm x 7.4mm (DIP-14)

- Approx. 2g

- 18V max, 15V typical

- Precision Op-Amp + Current Source Circuitry

- Amplification and Conversion of RTD Inputs for Industrial Measurement

- < 1 ms

- Compatible with RTD Pt100, Pt1000

- Dual Power Supply 15V recommended

- 4-20 mA Current Loop

- -40C to +85C

- Analog IC, not digital

- Through-hole DIP / PCB mount

- 18V max

- Temperature Measurement, Industrial Process Control

- Low drift, High accuracy, Monolithic Design

- 22.9mm x 7.4mm x 4.6mm

- Standard Dual-Inline Package thickness

- External Dual Supply (+15V/-15V)

- Instrumentation Amplifier IC

- Current Transmitter / Signal Conditioning IC

- Single channel

- Up to 24mA loop current

- Standard IC Black (Plastic) / Metal DIP

- DC to 800Hz bandwidth

- Not rated

- RTD Sensor / Current Input

XTR101 Trade Information

- All India

Product Description

Specification

| Base Part Number | XTR101 |

| Type | Current Transmitter |

| Mounting Type | Through Hole |

| Supplier Device Package | 14-PDIP |

| Part Status | Active |

| Packaging | Tube |

| Package or Case | 14-DIP (0.300", 7.62mm) |

| Output Type | Voltage |

| Operating Temperature | -40 deg C ~ 85 deg C |

| Interface | 2-Wire |

| Input Type | Differential |

| Current Supply | 20mA |

High Precision for Industrial Applications

Designed to support demanding temperature measurement and industrial process control roles, the XTR101 facilitates precise signal conditioning with minimal drift and high accuracy. The devices low offset voltage and exceptional linearity ensure consistent signal conversion, making it particularly suitable for interfacing with RTD sensors in process automation environments.

Flexible and Reliable Integration

The XTR101 is provided in a standard DIP-14 package with a tin/lead finish, making it straightforward to mount on through-hole PCBs. Its compatibility with Pt100 and Pt1000 RTDs and its recommended 15V dual supply accommodate a wide range of factory automation and control systems, providing flexibility for design engineers and system integrators.

Efficient Signal Transmission

Featuring an analog 4-20 mA output loop and fast response time of less than 1 ms, the XTR101 ensures prompt and reliable signal transmission over long distances. This efficiency is essential in harsh industrial environments, ensuring uninterrupted monitoring and control of temperature-driven processes.

FAQs of XTR101:

Q: How is the XTR101 typically used in industrial applications?

A: The XTR101 is designed for amplifying and conditioning signals from RTD sensors like Pt100 and Pt1000, converting these inputs into a reliable 4-20 mA current loop signal for temperature measurement and industrial process control systems.Q: What benefits does the XTR101 offer in terms of accuracy and stability?

A: With a low input offset voltage of 50 V max, high CMRR of 86 dB typ, and linearity error of 0.02% max, the XTR101 achieves high accuracy and stability, ensuring precise data collection and minimal drift over time in critical monitoring systems.Q: Where can the XTR101 be used, and what mounting method does it support?

A: Suitable for factory automation, industrial process control, and temperature monitoring applications, the XTR101 comes in a DIP-14 package for easy through-hole PCB mounting, supporting robust and reliable installations.Q: What is the recommended power supply configuration for the XTR101?

A: The XTR101 is recommended to be powered with a dual supply of 15V, allowing for a maximum supply voltage of 18V, ensuring optimal performance in various industrial environments.Q: When should you consider the XTR101 over other signal conditioning ICs?

A: The XTR101 should be considered when your application demands high accuracy, low drift, and reliable 4-20 mA current loop outputparticularly for temperature measurement with RTD sensors in industrial settings.Q: What is the process for integrating the XTR101 into a PCB design?

A: Simply mount the DIP-14 IC through the holes on a standard PCB, connect the RTD sensor to the input pins, provide a dual 15V supply, and route the 4-20 mA current loop output to your process controller or monitoring system.Q: How does the XTR101 handle input signals from RTD sensors?

A: The XTR101 amplifies and linearizes the small resistance changes from RTD sensors, converting them into standardized current signals for transmission and monitoring without the need for complex external circuitry.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Burr - Brown ICs' category

|

KK INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |